Kit numero uno has been cut! The joints have been dry fit. It’s a miracle (should I not say that yet?)

The CNC router showed up, got wired up, and and after a bit of troubleshooting, I was up and running.

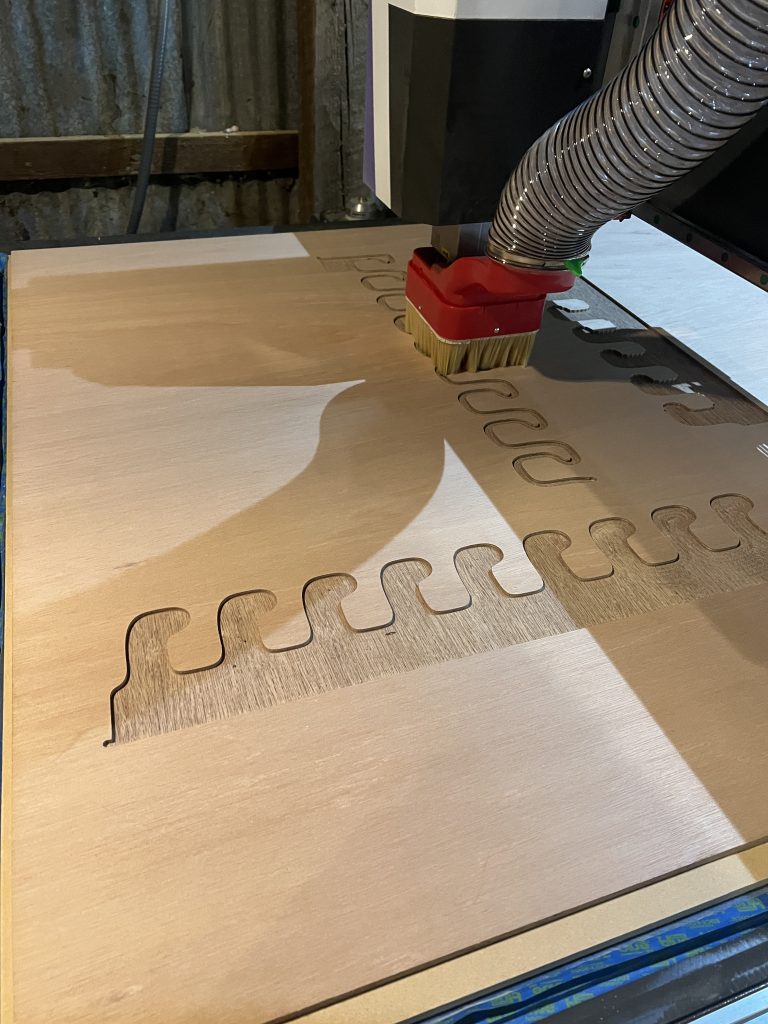

And I cut some test pieces out.

They even fit. The best thing about the puzzle scarf is that it forces everything to line up and leaves a clean, straight line on one side (typically the outside of the boat), so it doesn’t necessarily look like a scarfed boat.

Some refinement to the code and I dove into the first kit. Two of the scarfs were messed up, but entirely operator error from how I set up the CAM file. Luckily I had a good pile of plywood and cut the entire kit, 15 sheets in all.

I certainly learned a few things on this first “beta” kit- including that you need a good playlist to cover up for a few hours of CNC whine. I’m really looking forward to seeing this one go together, and am already working on another one. In the meantime, it’s time to weld up some oar towers and cut the stem from some beautiful Zena Forest Oregon White Ash.

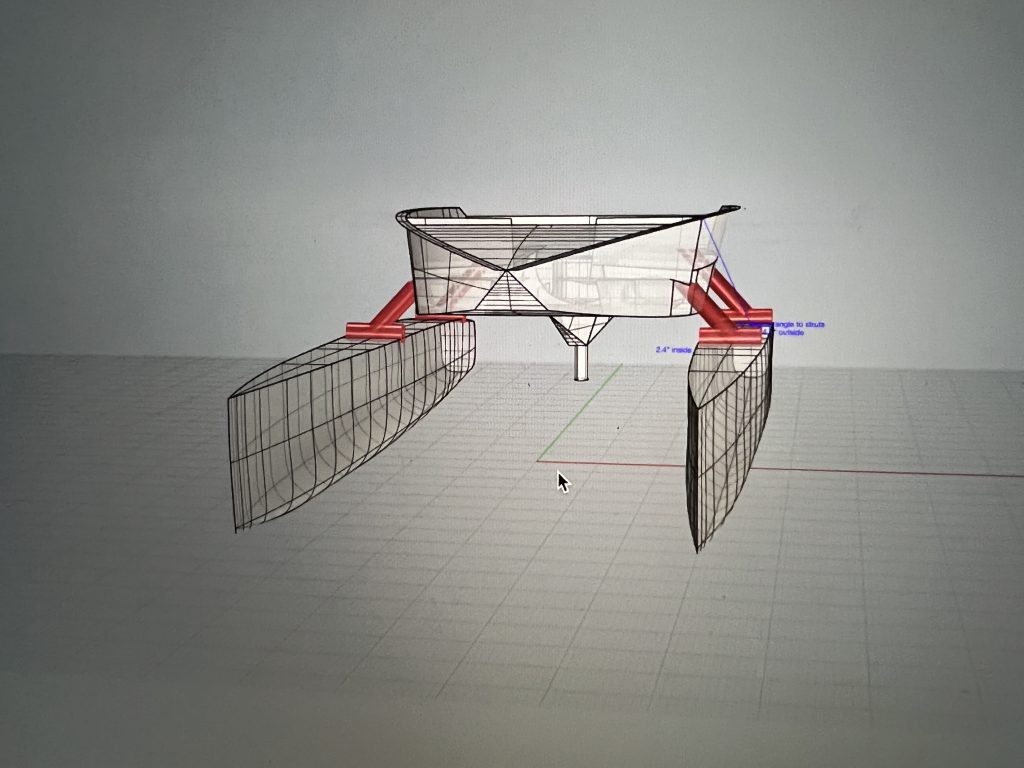

In the meantime, I’m been pretty distracted by my “skeeter” build (you can see the hulls in the background above)- it’s just one fun whacky boat:

I’m deep into the pod build – just finished putting the outboard mount together, not on to final fiberglassing and then finishing work.